China Injection Molding Procurement: Key Steps

The important meeting has recently finished, your new product has been approved, the schedule is tight, and the budget is… well, let’s just say it’s tight.. And suddenly someone—perhaps your superior or the finance head—says the fateful words that make any project manager’s heart skip a beat: “We should look at sourcing this from China.”

You nod, of course. It seems sensible at first glance. The potential savings can be massive. But your mind is already racing. You know the rumors, don’t you? Quality failures, endless communication gaps, shipments arriving months late and nothing like the prototype. It’s like balancing on a tightrope between a massive cost advantage and project disaster.

However, here’s the reality. Procuring plastic mold company needn’t be a roll of the dice. It’s simply another project with clear steps. And its outcome hinges on the approach you take. It isn’t about the cheapest offer but about choosing the right supplier and running the process transparently. Forget the horror stories. Here’s a practical playbook to nail it.

Initial Step: Prepare Your Information

Before you mention “supplier” or browse Alibaba, organize your internal data. In fact, most overseas manufacturing headaches stem from a vague or incomplete RFQ. Don’t assume a remote factory can guess your needs. Sending a vague request is like asking a builder to quote you for “a house.” The replies will range from absurdly low to exorbitant, none of which help.

Your RFQ should be bulletproof—clear, detailed, and unambiguous. This becomes the bedrock of your sourcing project.

So, what goes in it?

Begin with 3D CAD models. They cannot be skipped. Use standard formats such as STEP or IGS to ensure compatibility. This is the authoritative CAD geometry.

Yet 3D models don’t cover everything. You also need detailed 2D drawings. This details critical info missing from the 3D file. Examples include tolerances (e.g., ‘25.00±0.05 mm’), material grade, surface finish requirements, and functional callouts. If a specific surface needs to be perfectly smooth for a seal, or a particular hole diameter is vital for an assembly, your 2D drawing needs to shout it from the rooftops.

After that, material choice. Don’t label it simply “Plastic.” Don’t even just say “ABS.” Be explicit. Call out SABIC Cycolac MG38 (black), for example. Why so detailed? Because there are thousands of plastic variations. Specifying the exact resin grade ensures you get the strength, flexibility, UV resistance, and color consistency you planned for with plastic mold injection.

A good supplier can suggest alternatives, but you need to give them a clear starting point.

Don’t forget the commercial info. What’s your forecasted annual volume (EAU)? A supplier needs to know if they’re quoting a tool that will make 1,000 parts in its lifetime or 1,000,000 parts a year. Tool style, cavity count, and unit cost are volume-driven.

The Great Supplier Hunt

With your RFQ perfected, who will you target? Online sourcing is global but crowded. Locating vendors is easy; vetting them is the real challenge.

Your search will likely start on platforms like Alibaba or Made-in-China.com. They offer breadth but not depth. Use them to build a shortlist, not the final list. You’ll want to quickly build a list of maybe 10 to 15 companies that look promising.

However, don’t end your search there. Perhaps hire a local sourcing specialist. They do cost extra. Yet top agents deliver reliable, audited suppliers. They handle local liaison and oversight. On your first run, this is like insurance. Consider it timeline insurance.

Another tactic: trade exhibitions. If you have the travel budget, attending a major industry event like Chinaplas can be a game-changer. In-person meetings trump emails. Hold samples, talk shop, and gauge professionalism firsthand. And don’t forget the oldest trick in the book: referrals. Ask other project managers in your network. A recommendation from a trusted peer is often worth its weight in gold.

Sorting the Contenders from the Pretenders

After firing off that RFQ to a broad pool, estimates roll in. Some prices will undercut logic, others will shock you. Your task is to filter them down to 2–3 credible finalists.

What’s the method? It’s a bit of an art and a science.

Begin with responsiveness. Do they respond quickly and clearly? Can they handle detailed English exchanges? But the key: do they probe your RFQ? The best firms will question and suggest. Example: “Should we add draft here for better ejection?” or “Your tolerance may require extended CMM time—okay?” This is a massive green flag. It shows they’re engaged and experienced. A supplier who just says “No problem” to everything is a walking red flag.

Then confirm their machinery specs. Request their machine list. Seek samples or case studies of comparable projects. A small-gear shop won’t cut it for a big housing.

Next up: the factory audit. This is not optional. As you vet staff, you must vet suppliers. You can either go yourself or, more practically, hire a third-party auditing firm in China to do it for you. They dispatch an on-site auditor for a day. They confirm legitimacy, audit ISO 9001, inspect equipment condition, and gauge the facility. It’s a tiny cost for huge peace of mind.

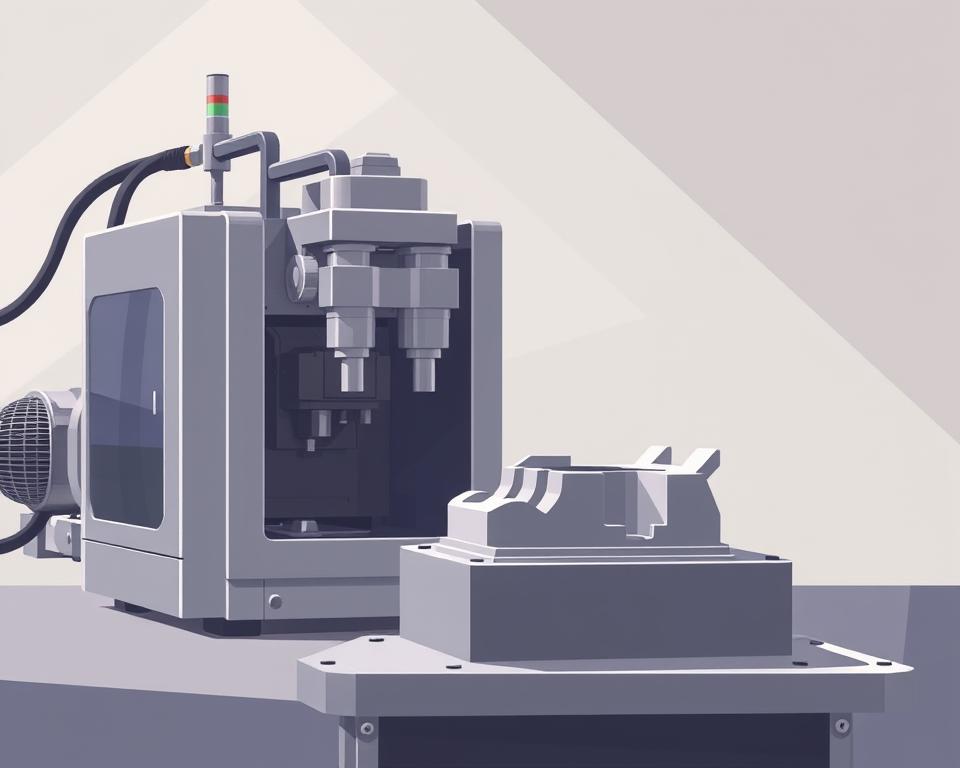

Converting Digital Designs into Molded Parts

Once you’ve chosen your supplier. you’ll agree on terms, typically 50% upfront for tooling and 50% upon first-sample approval. Now the process kicks off.

Your supplier’s first deliverable is a DFM analysis. DFM means Design for Manufacturability. It’s their professional review of your CAD. The report calls out sink-risk zones, stress-causing corners, and draft angle gaps. A detailed DFM shows expertise. It’s a two-way partnership. Together, you tweak the design for best manufacturability.

When you greenlight the DFM, they machine the mold. A few weeks later, you’ll get an email that will make your heart beat a little faster: “T1 samples have shipped.” These are the very first parts off the new tool. It’s your test of success.

T1 parts usually require adjustments. It’s par for the course. There will be tiny imperfections, a dimension that’s slightly out of spec, or a blemish on the surface. You’ll provide detailed feedback, they’ll make small adjustments (or “tweaks”) to the tool, and then they’ll send you T2 plastic mold in China samples. You may repeat this cycle a few times. The key for you, as the project manager, is to have this iteration loop built into your timeline from the start.

At last, you get the perfect shot. Dimensions, finish, and performance all check out. This becomes the “golden sample.” You formally approve it, and this sample is now the standard against which all future mass-produced parts will be judged.

Completing the Sourcing Journey

Receiving the golden sample seems like victory, but you’re not done. Now you’re entering the mass production phase. How can you keep part #10,000 matching your golden sample?

You need a clear Quality Control plan. Typically, this means a pre-shipment audit. Use a third-party inspector again. They’ll sample parts, check dimensions and finish versus your drawings and golden sample, and report. They provide a photo-filled inspection report. After your approval, you release the shipment and final funds. This audit shields you from mass defects.

Lastly, plan logistics. Know your shipping terms. Does FOB apply, passing risk at the ship’s rail? Or EXW, shifting all transport to you? These details have a big impact on your final landed cost.

Overseas sourcing is a marathon. It’s about building a relationship with your supplier. View them as allies, not vendors. Transparent dialogue, respect, and process discipline win. It’s a challenging project, no doubt. But with this framework, it’s one you can absolutely nail, delivering the cost savings everyone wants without sacrificing your sanity—or the quality of your product. You’ve got this.